How to overcome supply chain challenges

The daily pressure felt by staff and operators can be alleviated by reliability in the supply chain. The Caterer and Brita Professional look at how to meet the challenge

As operators seek fresh methods to counter rising costs, new research has found that hospitality businesses believe that improved reliability in the supply chain would enable better planning, reducing waste and inefficiency.

The survey of some 500 operators by The Caterer in partnership with Brita Professional has revealed that most operators had seen price rises across the board in the last 12 months, with the largest increases for ingredients (over a quarter had seen a 30% rise and over half at least 20%). This was closely followed by labour catering equipment, with 30% of respondents reporting a 20% rise in both.

Chris Fay, business account manager, at Brita Professional said the results were of little surprise. “All businesses within the supply chain are facing the same challenges with costs. We’re seeing this not only from a local level but more widely due to the current geo-political issues.”

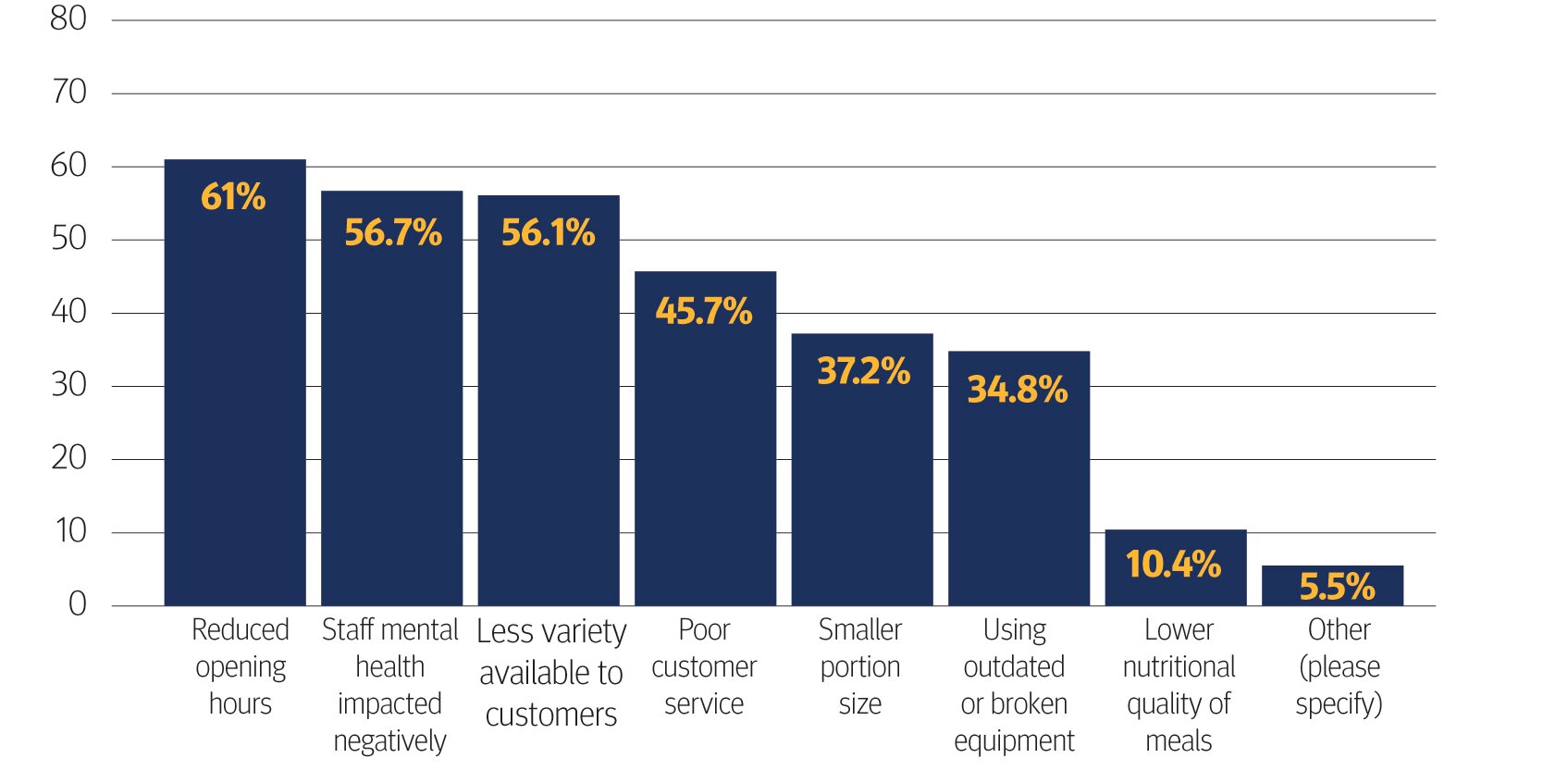

What, if anything, have you witnessed as a result of rising costs, labour shortages and supply chain disruptions?

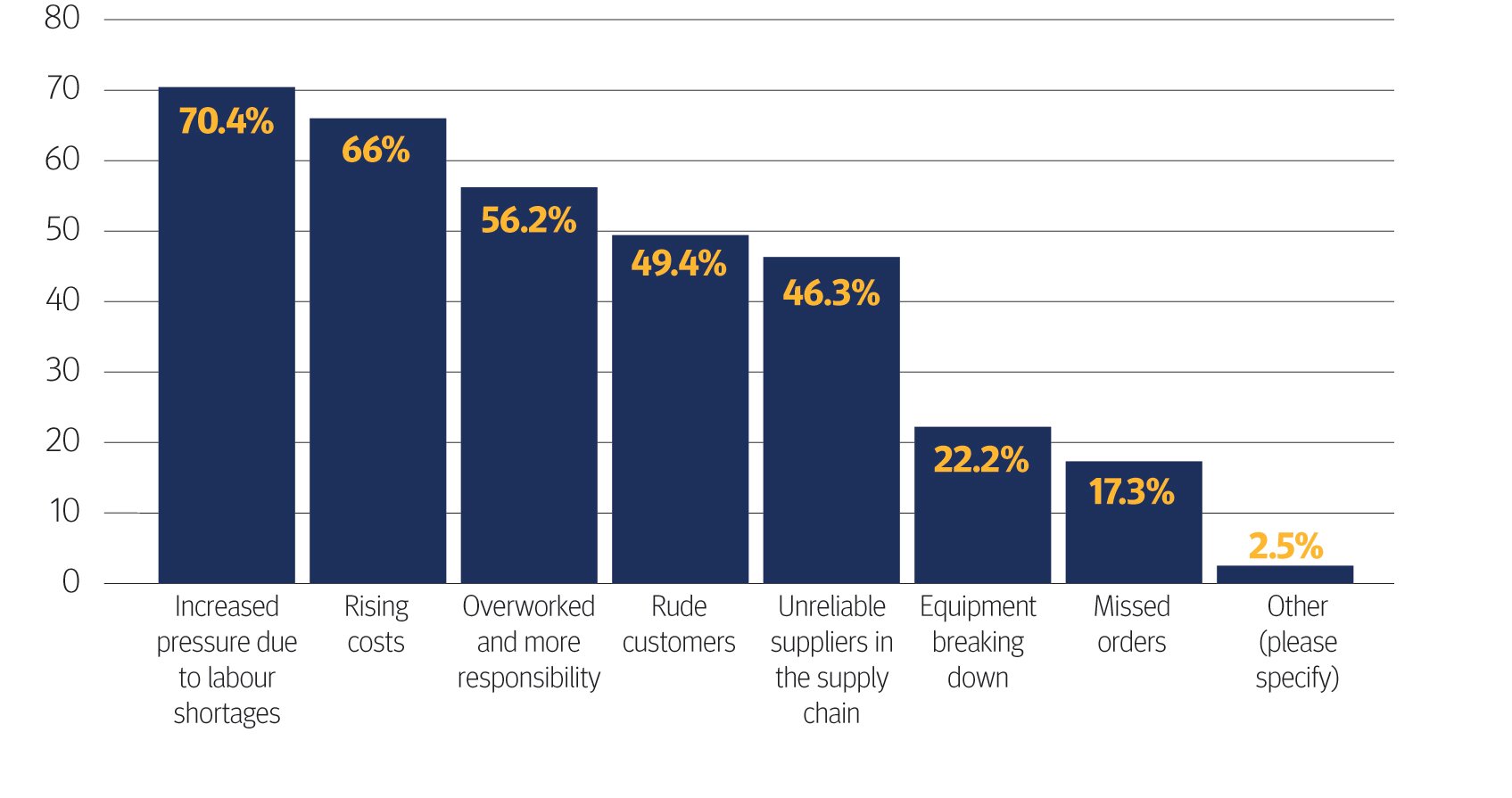

Respondents said the knock-on effect of rising costs, labour shortages and the supply chain were not just felt in menu price increases. Some 61% said the pressures meant they had to reduce opening hours, while 56% reported offering less variety to customers and 46% admitting that customer service had suffered. It’s little wonder then that 70% of respondents said staff and colleagues had experienced increased stress levels over the last five years, while 57% of operators claimed that staff mental health had been negatively impacted by the pressures they are working under.

Fay added that costs might be difficult to manage, but if operators took a proactive approach to maintenance of equipment to ensure the smooth running of the business, it would relieve some of the pressure: “Many of these costs are beyond the control of those involved, however looking at processes and ways of working can have a significant positive impact on both costs and staff wellbeing,” he said.

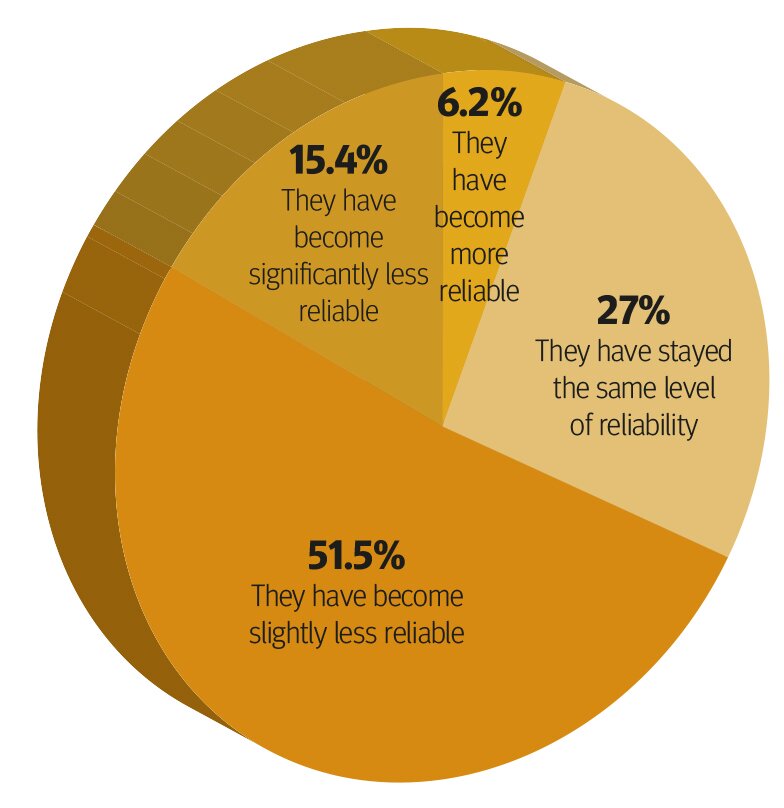

How has the reliability of your suppliers changed over the last five years?

“Over half of operators in the hospitality industry have begun buying from supermarkets and wholesalers directly, with others diversifying their supply chain [44%]. They have also ensured that their equipment is reliable to reduce stress for staff members [34%]and started using unusual ingredients which weren’t previously on menus [27%].”

With belts tightening, operators said they were also less likely to invest in energy efficient equipment (43%) or work with sustainable suppliers (40%), presumably because of a perceived cost burden. Meanwhile, a third of respondents said that reducing food waste was now more difficult, a phenomenon that is likely caused by a lack of predictability in the business and the pressures being felt by their colleagues.

With the background of such pressures, it isn’t surprising that reliability came out as the top requirement of a supplier, followed by quality and range of product. Fay said reliability was an issue that Brita was keen to focus on for its clients. “From a Brita perspective what we see clearly lacking is the basic knowledge of the adverse effects of untreated water on equipment, such as scale, decreased machine life, breakdowns and increased energy use. Fitting a water filter and exchanging on time will massively improve both sustainability and reliability,” he explained.

If your staff and colleagues have experienced increased stress levels over the last five years, what have been the main causes?

“On a wider scale to increase reliability within the supply chain there are a number of different things operators can do, including forming closer relations with suppliers to understand the challenges they face, working with suppliers to help avoid shortages and disruptions, having open discussions about needs at time of onboarding and creating more bespoke orders.”

Though 22% of respondents said their current supply chain was efficient and 28% said it was flexible, some 16% thought it was slow and unreliable. Taking into account a longer-term picture over 50% of operators thought that their suppliers had become slightly less reliable.

But it was recognised that any improvement in supply chain efficiency was a two-way street. Over 59% of operators said they were forming closer relationships with suppliers to understand the challenges they face to help avoid shortages and disruptions.

What are the most important factors when choosing a supplier?

The respondents also had some suggestions for redefining the procurement process in order to maximise ongoing reliability in the supply chain. One said the industry needed “to develop more dynamic, seasonal and ethical procurement”, and added that they were “currently working towards testing dynamic procurement”.

Another said working together was the key to greater efficiency. “Cutting errors in communication would certainly be an improvement and reduce last-minute problems, while we would like to consolidate the supply to reduce transport costs,” they said.

A third thought this process could be enhanced by technology: “We need better automation of communication so it’s a two-way partnership and nurturing key relationships to sustain trust and support.”

For Fay it comes down to communications too, with suppliers and operators working together to increase efficiency: “Have open discussions about the requirements of the equipment at the time of onboarding and ensuring your equipment is reliable at all times will really help reduce stress for staff members.

Go with the flow

The Caterer recently collaborated with Brita Professional on research into supply chain challenges, with the results discussed at a round table at Bacchanalia London in Mayfair. Rosalind Mullen reports

According to the respondents to the research undertaken by Brita, the largest increase in costs in the past 12 months has been in ingredients, closely followed by labour and catering equipment. Does that tally with the levels of price rises you are experiencing?

Chet Sharma (CS): From our primitive data it is close to double. We are a 33-seat restaurant and we work with small, independent farmers, including in India, so there is little buffer on costs.

Steve Hawkins (SH): In schools we have seen rises of 15%-30%, depending on the basket, and wage inflation of 9%-10%, so we are heavily reliant on our supply chain colleagues to mitigate costs and share the burden with clients, which is a challenge when funding hasn’t kept pace with inflation. We also look to dietitians and craft teams to flex recipes to suit schoolchildren, and we use small and medium-sized enterprises in the supply chain as they are a lot more agile in terms of their response time, dynamism and ability to scale-up faster than larger suppliers.

Heidi Stone (HS): We have also focused on SMEs and look for cost mitigation, and we are forward-buying as much as we can, which has forced us to work more in partnership with suppliers.

Tony Geary (TG): From my perspective the increase is closer to 30%-40%, so we are moving away from bigger suppliers. Zapote is a small, independent restaurant and so I don’t have the buying power.

Kirstin Hatherley (KH): On the equipment side, traditionally in January you would see a 4%-5% price increase, but since Covid some manufacturers are increasing their prices by up to 30%. If you are doing one-off sales, you can factor the cost into the quote, but for those doing design projects and trying to hold a price for six months, it gets complicated.

Julian Edwards (JE): Equipment manufacturers are saying that if you think you need something you can pre-order six months in advance and they will keep your name on file, so they are trying to be helpful, but we can’t predict that far ahead.

Have you changed your menus or do you pass on the rising cost?

CS: We are a small restaurant so to keep it busy, we take less. Expense accounts are drying up a bit and that is having an impact on how we design the menu, particularly at lunchtime. When we opened BiBi in September 2021, the chef’s menu was £65 and now it is £125. But we are not making more money – it just keeps the lights on. We have made some compromises. For instance, we still use truffles but we also use liver, and that ticks the sustainability box.

TG: We change menus every few days, but there are hidden costs as you then have to update the website, social media and paper menu. Our business model was £58 [spend] a head and it is now coming in at £51. We prefer having a full restaurant and we are getting repeat guests, so we will build that up.

Are supply chains challenging?

TG: We place orders with suppliers every day. The issue is that suppliers might not be up front about what they can get or be late, so you need to change the menu on the day. Sometimes it is out of their hands. Our guests often order a dish they saw on Instagram and if we don’t have that dish they are disappointed.

Chris Gamm (CG): At Springboard, the sort of equipment we look at could be training products. We typically go for big, well-known brand names who we know will provide the best on the market, ensure that we comply with legislation, stay ahead of trends and could bring a bit of a following to us through people who follow their product.

Can you get the same level of support from smaller suppliers?

SH: The hidden costs are the disruptive supply chains, because if school caterers have a sudden change of product there can be an emotional impact on them. If there is a product switch, the menu changes, their day changes and their resilience changes, so we need to support them.

HS: We look at forecasting supply and identifying product swaps for late notice. There is not one perfect answer. You do everything you can.

SH: We have 4,500 suppliers in the UK and we see it as essential to develop that relationship to make us successful. We work with SMEs to help them grow and we bring partners together, too. For example,we recently invited 150 suppliers to a conference to articulate our ambitions and see how they can help us with innovation. We give them a long-term vision of where we are going in the public and private sector. That forward-planning is critical.

More than 50% of respondents said suppliers have become less reliable over the past five years. Is that your experience?

JE: I see suppliers in many guises – equipment and food suppliers and so on – and there have been major issues. For instance, in the past few months we couldn’t get UK chicken. We also liaise with contacts in France and the Netherlands and they have the same food and labour cost issues. So, it is not Brexit, it is the world status and economy. We expect contractors and suppliers to have a levelling-off agenda. A lot of contractors worked to a £2.50 meal and we need to get back to that.

CS: It is a global problem. We have infantile business interests in North America and the Middle East, and North America is hit harder in ingredient pricing and labour. It is easy to fall back on Brexit, but there are also the effects of the pandemic and the war. Some 30%-40% of food in Europe comes from Ukraine.

Recruitment is a challenge. How is this affecting your business?

CG: Recruitment costs are a big issue and the industry is not thinking differently enough about attracting staff. It needs to do more to attract those who, for instance, face barriers. At Springboard we work with people who face barriers and of our trainees about 74% stay with businesses over a year. So, rather than concentrating on the shining staff who may leave after six months, we need to give recruitment opportunities to different community groups.

SH: In the non-education side of Sodexo this year we have started working with prisoners and ex-offenders and rehabilitating them.

CG: We need to look at different shift patterns too. Students, older workers or parents will work if they are offered flexi-time and shorter shifts.

CS: Post-pandemic we changed our system to four days on three days off, a 48-hour working week, whereas previously 70 hours was the industry norm. Wellbeing is a buzzword. As a small independent, I worry about staffing more than food costs. I don’t know where our staff will come from among the younger generation.

CG: It’s about making time to get out to schools, telling a story and nurturing the next generation. Everyone in the industry has a role to play. People who are aged 15 to 16 will be your workers in the future.

SH: FutureChef is good at attracting young talent, who you can then mould and shape and give them purpose and passion. Our research said initiatives such as sustainability are important, but some respondents said they have to let it go as they can’t afford it.

HS: What it has made us do is prioritise more effectively. For instance, looking at reducing waste or reducing meat in menus.

Is it a struggle to get people to look after equipment?

CF: Customers look at overheads and costs, but if they don’t maintain their combi-oven it will cost them more in the long-run. Preventative maintenance is key to keeping those profits and keeping staff stress levels down.

KH: A lot of businesses aren’t doing any planned maintenance. When we take over a contract and start doing regular maintenance we find the reactive maintenance figures come down. You need to do at least an annual service. A lot of big chains don’t do that, but it does help extend the life of catering equipment and is better for the environment. It also prevents the stress of trying to get spares and supply issues. Before Covid we could get them the next day, but now some components can take four or five weeks so that affects menu planning.

JE: A year ago, as a result of chatting to [school food body] LACA about energy saving tips for caterers, we produced a detailed document with input from sectors including technical equipment. We are now working on phase two with a group of caterers that had high-frequency call-outs for kitchen issues. Every contract will have a maintenance programme that forms part of the chefs’ daily checks. It has a checklist of 17 points, such as ensure all water appliances have calcium treatment; empty the debris trap on the defog unit every week and strip it down once every six weeks; wash-off solutions to preserve all seals, even on self-clean equipment. It is painful for chefs, but the maintenance programme will stretch the life of your equipment and make savings.

KH: Kaitech is collecting energy-saving data. Its survey for a chain of restaurants found that chefs are turning on the chargrill at 9am and not serving food until 11.30am, with extraction representing 40%-50% of energy usage. They could save £750,000 by switching it off until 11am.

When asked what else they witnessed as a result of rising costs, labour shortages and supply chain disruptions, the most popular answers were reduced opening hours and impact on staff mental health. Has it become intense for your teams?

HS: We have chef-managers who are looking after big schools and they are under huge pressure if a delivery doesn’t turn up. A chef-manager has to be multi-skilled to look at marketing, compliance, ordering, cooking and client interaction. It is a challenging role, so they need more support.

TG: We close on Sunday and Monday for the welfare of the team and to attract staff. The business demand is there, but we know we would lose half the team if we changed. We do 45 hours a week, straight shifts. I work from 9am to 1am and haven’t drawn a salary for six months.

CG: There is a societal issue. Pre-Covid 11% of our trainees said they experienced mental health issues and now it is 27%. It is a hard-paced industry and people are having to work longer hours because there is a lack of staff. The cost of living crisis means it is a perfect storm. All employers have a duty of care, but what we have seen driving the shortage of staff is the over-promotion of managers, which adds another level of pressure. Proper training is more important than ever.

On procurement, how could the supply chain be improved in terms of decision-making and planning?

HS: Transparency. I would call that out in our supply chains – understanding where our food comes from and how it arrives and reporting on that. I mean evidential, factual targets around sustainability.

JE: Yes, it would be useful if suppliers explained what good, stable products will be available for us in the next six months and which products will be a good price. I want to see raw intelligence from suppliers. And open communication with customers is crucial, too. Allergens are important and the menu must reflect last-minute changes of ingredients.

About BRITA

BRITA was founded more than 50 years ago and has established itself as one of the leading experts in the field of water filtration. The family business manufactures water filtration products for households and businesses in more than 60 countries.

BRITA filters improve machine longevity by reducing limescale build-up and deposits of unwanted minerals. By guarding against potential damage, businesses can improve the reliability of equipment.

BRITA Professional products are designed to produce the best filtered water for food and beverage preparation by removing particles, metals, minerals and chlorine that have an unfavourable impact on the taste, appearance and aroma.

To find out more visit www.brita.co.uk/rely-chain-hospitality