FEA Guide 2024: Hot and cold holding displays – essential selection advice

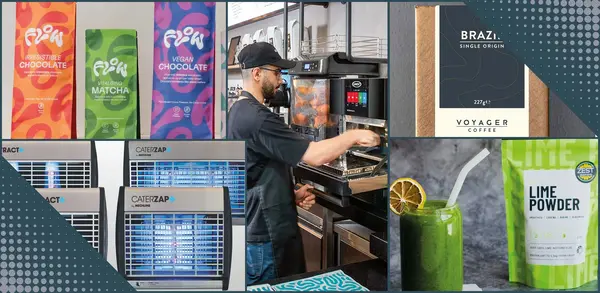

From food-to-go to pâtisseries, display units can make or break your revenue generation capabilities

Displays are the preening show ponies of the hospitality equipment world. These front of house cornerstones need to look good, maintain temperature – whether for warming or chilling – and operate efficiently.

Before choosing display equipment, you need to know the space available in your venue, not forgetting to take into account extra room to ensure any ventilation outlets on the appliance aren’t blocked by being jammed up against a wall or other equipment. If there’s an overall design theme front of house, finding a merchandiser to match can be vital to creating an appealing visual flow which helps to boost impulse sales.

Internal lighting for display cabinets is another important consideration. The illumination should be bright yet subtle enough to showcase your wares in the most appealing way. And if you choose a unit which uses LED bulbs, they have the double benefit of being inexpensive to run and therefore being good for the environment too.

You need to know which type of unit is right for your needs as well. Larger capacity requirements could benefit from multidecks with multiple shelves, or deli-style venues might plump for serve over display counters, while smaller or more specialised sites may only need countertop units.

The FEA’s advice

As hot holding systems need to be operating constantly to work effectively, they can be significant users of energy. Choosing hot holding equipment that is as efficient as possible helps to improve the sustainability of your business. When selecting this type of equipment, ensure the product is held at the required temperature for the expected display period without drying out. Specify the size of cabinet which suits your expected demand and don’t oversize it. Once food falls below 63°C, it will need to be used within the two-hour period or risk being wasted.

Look for equipment with features like individually-controlled temperature zones. Not only will this allow you to keep a wider variety of menu items on hand, but you can turn off unused sections during quieter times. Simple design touches like metal lids for individual food containers can increase thermal conductivity, helping to reduce energy consumption.

Like most categories of foodservice equipment there are many different solutions for hot holding. And just like every equipment purchase, operators have to choose between cheaper, bare bones models and more expensive alternatives with more advanced technology. It’s important to balance initial vs lifetime equipment cost when considering what is right for your business, as the more expensive alternatives often have lower energy consumption, helping to keep running costs down as well as improving the overall sustainability of your operation.

Features like digital temperature controls, smart airflow systems, individually-heated shelves and zonal air circulation not only help to keep food hot for longer, without deterioration, but can also enhance the efficiency of the unit.

When it comes to merchandisers, choosing hot holding systems with doors can have possibly the most significant effect on energy consumption and sustainability. Thermal shedding is inevitable in open fronted units. This not only increases energy use, but can also add to the workload on other energy hungry systems, like ventilation, in order to maintain comfortable temperatures for staff and customers.

Read more from the FEA Guide

Refrigeration – how to choose the correct equipment >>

Prime cooking – the kit to help you be energy efficient and environmentally clean >>

Multicook/multifunctional equipment – the combi-oven: the tool that does it all >>

Microwaves and rapid cooking – are microwaves a secret weapon in the kitchen? >>

Warewashing – here’s how to make the decision on the perfect warewasher >>

Photo: Howard Walfish via Flickr