Clean and green: why bringing your laundry in-house is the sustainable choice

Sparkling bedlinen and immaculate chefs’ whites are a business essential, and one that can be achieved by bringing your laundry in-house, according to research conduced in partnership with Miele. Glynn Davis reports

Sustainability is the word on everyone’s lips right now and hospitality operators are having to rethink how their businesses operate to align with environmental values. Research undertaken by The Caterer for Miele found that 56.7% of respondents regarded sustainability as very important to their organisation’s mission and values, while a further 33.3% regarded it as fairly important, which indicates the way the wind is blowing for many companies.

And although laundry has not been given particular consideration in terms of sustainability, it’s an area which could have huge benefits to the environment when approached with due care and consideration.

Bringing laundry services in-house can generate myriad benefits for businesses, including numerous environmental upsides, which should see it become a bigger feature of the industry in the future and replace outsourcing for many operators.

But judging by the findings from the survey, there is arguably some disconnect between these figures and companies’ recognition of the benefits that in-house laundry can bring, because at present a rather modest 41% of businesses have an on-premise laundry (OPL) and a further 8.8% state that they would like one.

Sam Dent, marketing manager for Great Britain and Ireland at Miele Professional, says: “Given the sustainability trend and how more and more companies are turning to more sustainable practices I think OPLs will continue to grow.”

Making sustainability luxurious

One organisation that has gone down this route is Daylesford Organic, which encompasses farm shops, pubs, spas and holiday cottages as well as a cookery school. The company puts sustainability at its heart and has set itself challenging targets to reduce its impact on the environment across all areas of its business, including its laundry requirements.

There has been the perception, according to Will Dennis, head of sustainability at Daylesford Organic, of luxury and sustainability as mutually exclusive, but he argues that this is incorrect: “Most people think that sustainability and luxury can’t coexist, but we disagree. If we can provide both by producing laundry to a very high standard in a sustainable way, using renewable energy sources such as biomass, our customers can enjoy their time at Daylesford Orgnaic without worrying about the environmental impact.”

Initially the company had laundries across two different sites and the team outsourced the cleaning of linen from its holiday cottages. However, as the business continued to grow, the on-premise provision had struggled to keep up with demand.

The team wanted to bring all the laundry in-house and into one unit to enable it to take advantage of its biomass boiler and more easily manage quality standards while saving on costs and cutting transport emissions. In-line with the business’s core values, it was key that the new laundry solution was as sustainable as possible.

Dennis says: “Every single part of our business, from our kitchens through to our spa and our holiday cottages, produces laundry in some form. It’s important for us that every single customer experiences the same high standard when they come to Daylesford, whether that’s having their meal cooked by a chef in pressed whites or visiting our spa and using a lovely clean bath towel and robe.”

Clean up your act

The research found that 82% of respondents regard control over the cleanliness of their laundry as very important.

“Centralising laundry has improved efficiencies and maintained quality compared to when we had six different suppliers with different standards. For our business, whether it is chef’s whites, napkins or spa towels, the expectations of our guests is high,” Dennis says.

According to the survey, there is widespread recognition that an OPL can help in this area, with 85% of respondents strongly or slightly agreeing that an OPL helps or would help to maintain standards. As many as 75% strongly agreed or slightly agreed that an OPL also helps to protect a company’s reputation and 90% strongly agreed or slightly agreed that sustainability is an important consideration when choosing laundry and cleaning solutions.

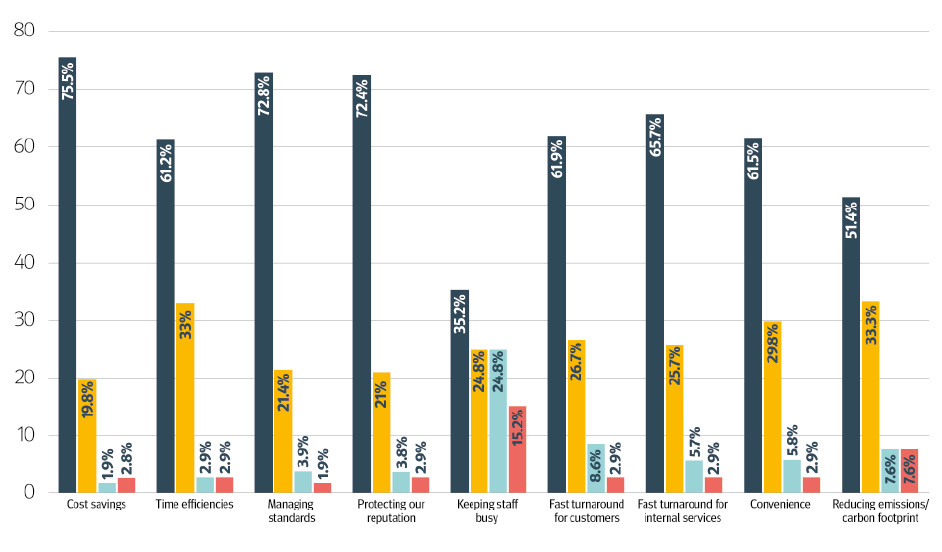

Needless to say, companies are also looking at cost savings to ensure business success and laundry is very much under the microscope. Cost is certainly an important factor for those companies considering switching to an OPL, with 95% of respondents regarding costs as very or fairly important to their decision-making in this area.

“Sustainability can sometimes come at a cost, but when it comes to the laundry room, that isn’t always the case because investing in sustainable equipment means you become more efficient, you have less machine downtime, lower utility bills and ultimately longer-term cost savings,” explains Dent.

Dennis says Daylesford Organic has managed the costs of its OPL – and its sustainability – by analysing all its procedures and identifying waste. This was reflected in the way it leveraged its vehicles. Its vans bring food supplies to its London stores, but also transport dirty laundry back to its centralised OPL facility. “We capitalise on our network. The key thing is to streamline your business,” he adds.

This scenario is recognised by Dent, who says: “You can control the high standards of laundry more easily. Lifetime costs of appliances and associated services will be lower than outsourcing. If you cut out the time it takes to transport laundry to and from an outsourcer, it not only means time savings but there is also the possibility to reduce the amount of linen and towels you need to buy.”

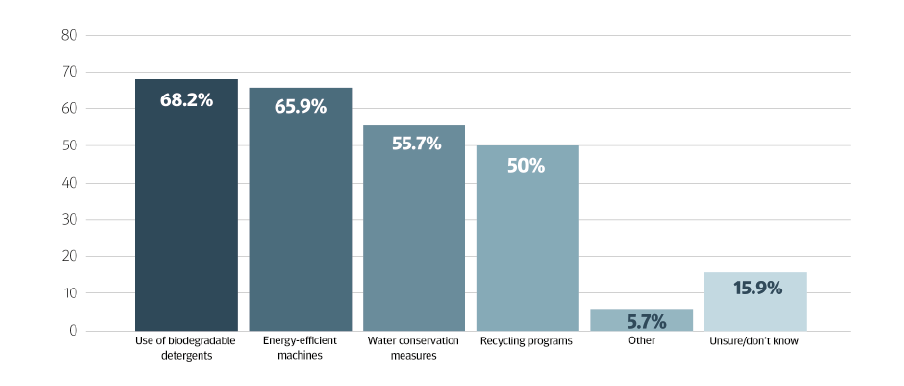

The survey found hospitality companies expect various sustainable practices to be derived from OPLs. Some 68% expect the use of biodegradable detergents, 66% expect energy-efficient machines, 56% expect water conservation measures and 50% expect recycling programmes.

Daylesford Organic has very much benefited in these areas from its adoption of an OPL and the selection of low-impact equipment from Miele, whose kit it has been using for 15 years. Dennis says: “The machines weigh the laundry exactly and will auto-dose detergents to a fine degree, which ensures only the necessary amount of detergent is added to each cycle. They also carefully manage water usage. You get a service that’s as efficient as you can get.”

Space savers

The survey found that space is also a major consideration for hospitality companies. Dent says the firm’s smallest laundry equipment can be stacked within a metre squared space and is very efficient, contributing to 22% water and 28% energy savings compared to previous models. The heat pump dryers in the range are 60% more efficient compared to conventional drying technologies and also have a 25% reduction in cycle times compared to previous models.

For Daylesford Organic, choosing efficient machines that take gentle care ensures fabrics last longer and don’t have to be replaced as often, resulting in less waste to landfill. The machines have a range of specialist programmes, which optimise spin speed and moisture levels and reduce the amount of time the items need to spend in the tumble dryer, improving productivity and energy efficiency.

Energy reduction is certainly high up the agenda for hospitality businesses, with the survey finding 72% have taken steps to address energy costs. During the current cost of living crisis, costs are uppermost in the minds of business leaders and it is no surprise that it is the most important factor when considering an OPL, with 95% of respondents regarding it as very or fairly important.

Other factors also figure very highly, including time efficiencies at 94%, managing standards also at 94% and protecting reputation at 93%. All these are well catered for by an OPL, according to Dent, who suggests it allows operators to be hands-on in maintaining and controlling the high standards guests expect across a whole business, including back-end activities.

“With an OPL you can ensure the customer has the very best quality of linen. From previous research we also know that many hotels are not able to offer personal laundry requests, but with an OPL this would be much more manageable, demonstrating the hotel’s ability to go the extra mile,” he says.

This control has been particularly important to Daylesford Organic. Dennis says: “There was a creeping feeling that we were reliant on a lot of external parties and we wanted to take back control. Companies need to consider this.”

This fits into the narrative of businesses needing to have greater control over their supply chains to have much fuller visibility of their environmental footprints, and can stand firmly behind any claims of sustainability and adherence to wider environmental requirements.

“Laundry is not something you talk about, but if our behind the scenes activity did not meet our sustainability standards, we’d have a reputation problem waiting to happen. Once we’ve shown visitors the sustainable farm, I can also take them into the laundry, because we’re just as comfortable with both our front and back ends. It’s all about integrity. We’ll be finding that people are taking back control and collaborating [on laundry],” says Dennis.

Lasting legacy

But embracing an OPL cannot be achieved alone and choosing a partner is vitally important. This can involve a variety of factors, according to the survey, with reliability regarded as very or fairly important by 96.9% of companies.

The solution certainly needed to be reliable and durable for Daylesford Organic in order for it to get through the 1,000kg of washing generated each day and operate non-stop between 6am and 10pm. The team also needed to be able to rely on the equipment to deliver the consistently high standards expected by their guests.

The need for reliability from an OPL partner was closely followed by price at 96%, service at 96%, efficiency at 95% and quality at 94%. For Daylesford, the key criteria is working with businesses and suppliers that have similar mindsets in the way they approach business and sustainability.

“We’ve been using Miele for 15 years and it was important to us to keep that legacy alive, not only because of the aftercare we’ve been shown, but also because of its advancing technology, focus on developing more eco-friendly models, and the ability to connect the machines to our biomass boiler,” says Dennis.

This is reflected in the company’s recently-launched digital solutions, which include MOVE, which contributes to delivering efficient machine, data and process management, whereby business owners can manage machine data and workflows in-house that saves time, money and frees up employees to concentrate on other tasks.