The latest in cleaning and hygiene technology

Covid-19 has triggered sweeping changes across the foodservice and hospitality sector, compelling operators to juggle more stringent and more frequent hygiene protocols despite uncertain trading and staff shortages.

“Following the relaxing of all rules in England, catering teams have undertaken risk assessments to ascertain whether all or some of the changes made are required or whether they could adapt and implement some of the ‘enforced’ changes to enable a better and more efficient operation,” says Rupert Lynch, client relationship manager at food procurement expert Allmanhall.

As Covid-19 risk assessments remain mandatory, social distancing, PPE and revised working patterns – such as staggered arrivals and departures, shift working, flexible rotas and kitchen team ‘bubbles’ – look likely to stay on the menu, says Lynch.

And there are few signs a skittish public is ready to dispense with the super-hygiene measures trialled over the past 18 months. In fact, recent research by KAM Media for consultant Food Alert reported that 55% of consumers wanted to see extreme hygiene measures, such as sanitising stations, socially-distanced tables and visible safety certificates, become permanent fixtures. Cleanliness and Food Hygiene Ratings (FHRs) ranked as their third and fifth top reasons for choosing a venue to eat out.

Similarly, research from Wrapmaster owner Cofresco Foodservice found hygiene was the key consideration for 74% of people dining out and that 71% checked out hygiene standards.

Close contact

Clearly visible cleaning processes will boost customer confidence, advises Lynch: “Revisit and update cleaning schedules, concentrating on key touch points, cleaning every two hours, and cleaning seats and tables after every sitting. Look to reduce contact with certain surfaces and equipment, removing unnecessary furnishings and other items from eating and cooking areas which can harbour germs.”

With FHRs operating as decision makers or breakers, it is perhaps unsurprising that many cleaning teams have taken inspiration from the different-hued chopping boards their food prep colleagues use to prevent cross-contamination, as well as employing colour-coded brushes for different cleaning tasks. This ensures the same equipment is not used for food-contact surfaces and floors, observes Mariane Hodgkinson, hygiene specialist at Hillbrush.

To keep on top of so many frequent touch-points – from handles and lift buttons to vending machines and condiment pots – it makes sense to simplify processes by using products that are faster and easier to use, yet still protect against multiple pathogens, advises Lynne Snoding, sector marketing manager for foodservice and contract catering at cleaning specialist Diversey.

Its range includes several lines that clean and disinfect effectively and simultaneously but are safer for humans and surfaces than traditional virucidal disinfectants. Diversey’s Oxivir cleaner disinfectant wipes – based on accelerated hydrogen peroxide – kill viruses in 30 seconds, 10 times faster that conventional versions while its new Degregerm 24 Shield spray zaps microbes on non-food contact, and dries into a thin film on non-porous surfaces that protects for up to 24 hours. This, says Snoding, can reduce cleaning frequency from every two hours to just twice a day.

“Not only is it crucial to correctly clean kitchen equipment in order to adhere to food standards and environmental health legislation, but a regular cleaning regime will help to extend the lifespan, maintain manufacturer warranties and ultimately save energy and water,” advises Julian Fisher, head of marketing at spare parts and accessories supplier First Choice Group.

Recent investment to boost stockholding to 90% means First Choice is confident it can overcome the challenges caused by Brexit and recent transportation delays to deliver its wide range of manufacturer-recommended OEM-branded cleaners for leading warewasher, combi oven and microwave brands.

Get a handle on it

Many appliances come equipped with integrated sanitation solutions that can help chefs navigate the significant challenges and extraordinary amount of change now required of them to keep customers safe, points out Steve Hemsil, sales director UK & Ireland at Welbilt.

Its new Convotherm Maxx Pro combi oven is certified for unattended cleaning that can be pre-programmed via the cleaning scheduler. Along with antibacterial and antimicrobial handles, it offers four cleaning settings and three cleaning modes, including Eco and Express modes and a HygienicSteam function for cooking utensils.

According to Toluna research for Cofresco, 93% of customers would feel better knowing chefs had updated to equipment that can be cleaned and sterilised regularly, while 81% would be reassured if loose cling-film rolls were protected from cross-contamination by dispensing systems such as Wrapmaster’s robust plastic cutter box, that can be wiped down and disinfected in a dishwasher.

Track your cleaning

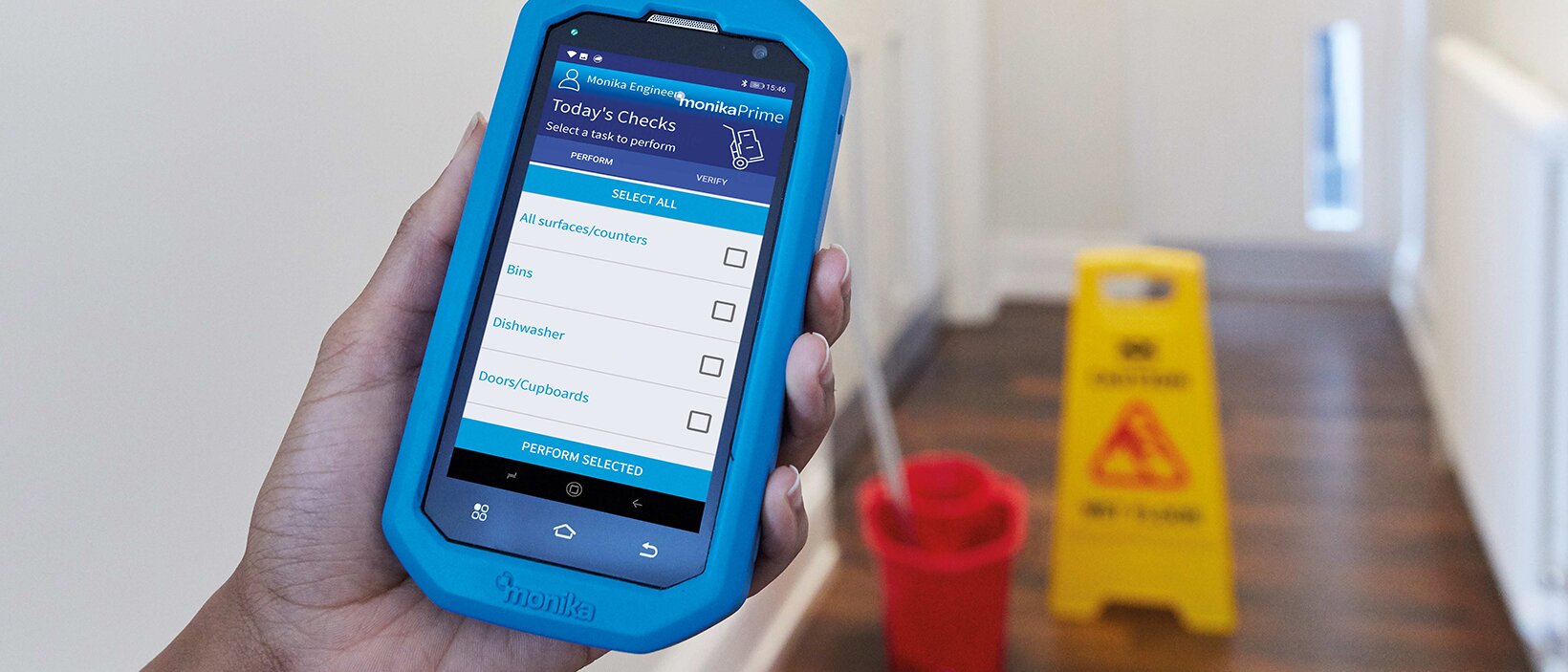

“Technology can help caterers optimise their cleaning regimes to reassure customers when many operators are experiencing unprecedented staff shortages,” says Tim Gamble, executive chairman at Monika.

Its cloud-based MonikaPrime technology (pictured) provides traceable records of staff and equipment performance and compliance via a smart PA, Bluetooth food probes and sensors that monitor refrigeration equipment 24/7.

The team management module can schedule essential hygiene tasks and issue reminders to wash hands, clean equipment, change cloths or temperature-probe food.

Similarly, workforce management specialist Unifocus’s task management software can integrate mandated cleaning procedures and even allocate a staff member to visibly perform cleaning procedures during peak times. Its mobile-based pre-screening tool will reassure guests that staff had no Covid symptoms before their shift while touchless technologies – such as phone-based mobile timeclocks or physical smart time clocks that sign staff in through biometrics, cameras or swipe cards – reduce areas of potential cross-contamination.

“Being transparent about the protocols in place is important to help guests feel comfortable because it allows them to understand the lengths a property takes to keep them healthy,” notes chief executive Mark Heymann. The group’s Knowcross operational optimisation software can help operators go the extra mile by ensuring staff respond swiftly to guest safety concerns and requests, while its guest survey software helps identify potential areas of improvement.

“You never get a second chance to make a first impression, and this is so true when it comes to hospitality. A clean, tidy venue is more important than ever, with more than half of consumers wanting hospitality venues to have extreme hygiene measures evident, displayed and transparent,” says Mike Williams, operations director at Food Alert.

With 49% of consumers operating a ‘one strike and you’re out’ policy towards perceived poor hygiene, Williams warns: “Venues simply will not prosper if they fail to get the fundamentals right and meet the increased expectations of consumers on food hygiene and cleanliness.”