Less is more when it comes to efficient warewashers

The best warewashers are super-economical, recycling water into the next wash and consuming minimal electricity. Lisa Jenkins reports

With sustainability and economy top priorities in foodservice, operators require warewashing equipment that minimises water, fuel and chemical use, saving the environment as well as money. The hospitality sector also relies heavily on its warewashing machines to deliver reliable and consistent levels of cleanliness, given that any blips can slow down service.

Luckily, suppliers are ahead of the game, with dishwashing wizardry in all sizes, from the smallest undercounter models to industrial rack conveyor machines.

Procurement hints and tips

- Buy a dishwasher that is appropriate for your size of business. It is vital that the warewasher turnaround time matches your table turnaround time

- Businesses that require tableware to be used straight after washing should consider getting a model with an auto-open feature to dry the cleaned tableware more quickly

- Consider the machineâs capacity, and how to integrate it into the flow of your kitchen

- Connected technology is a topical issue, with apps that let you monitor potential machine faults remotely

- Research the energy and water efficiency of the machine

- Equipment with control sensors allow for precise wash cycle timing and basket spacing to reduce water consumption, ensuring that no empty spaces are being washed

- Remember, straightforward button controls and universal signs make life easier for the operator. A reliable, easy-to-use warewasher is sometimes the best way to go.

Water quality also plays its part in cutting warewashing costs. Water softening equipment can improve a warewasherâs efficiency and wash results, as there will be no need for staff to polish any water marks off crockery, cutlery and glassware.

Hard water is estimated to be responsible for around 70% of equipment failure incidents, and water softening treatments can minimise machine downtime caused by limescale build-up.

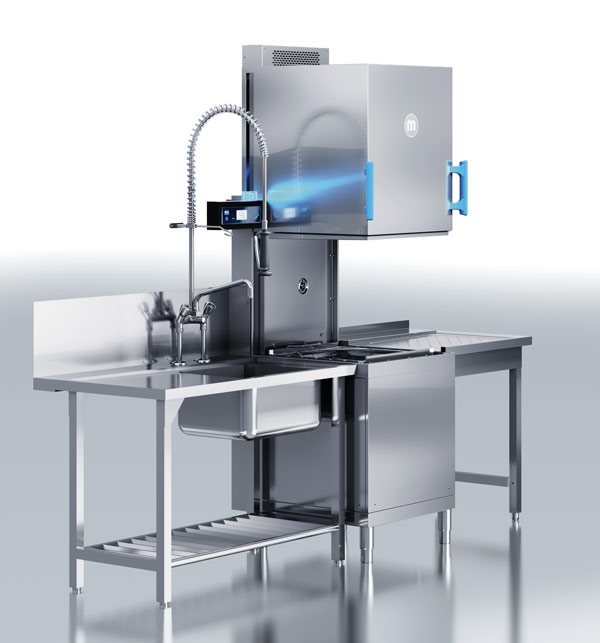

The no-haul hood

Lifting the hood manually on conventional hood-type dishwashers requires around 80 newtons of force â" itâs the equivalent of lifting a bucket of water above your head. Busy kitchens can put up to 120 racks through the machine in one session, and smaller kitchen staff in particular may end up having to do some awkward stretching as well as getting tired.

And that makes the automatic hood on Meikoâs M-iClean H machine an innovation worth considering. It removes the need to stretch awkwardly or lift heavy loads when loading or unloading the dishwasher. That improves working conditions for kitchen staff by helping to reduce excessive movement and the incidence of back and shoulder pain.