Winterhalter launches new series to its MT conveyer range

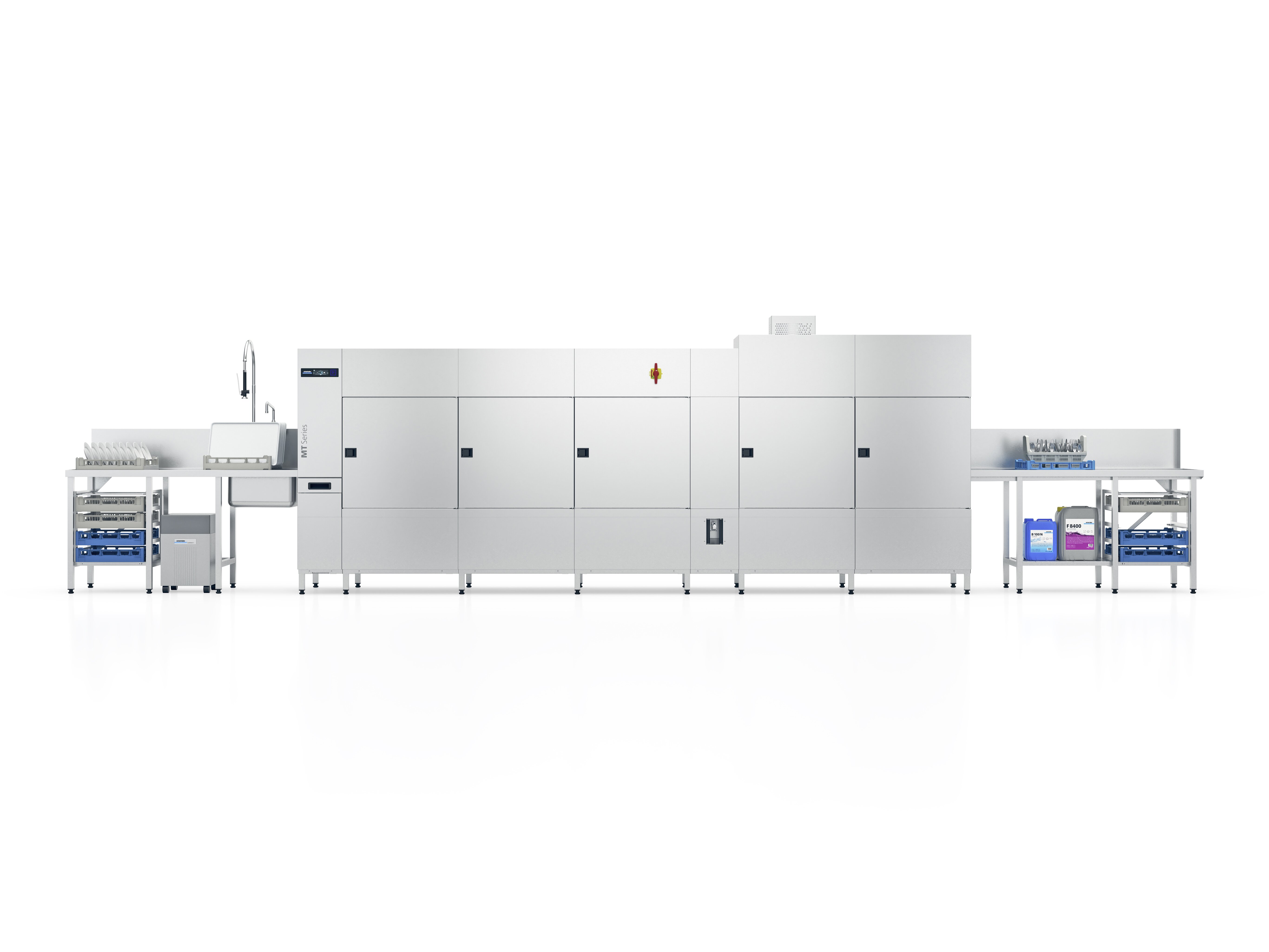

Warewashing manufacturer Winterhalter has launched new versions of its MT (multi tank) conveyor dishwasher systems.

The new MT is based around a modular system that allows machines to be configured and constructed to match a commercial kitchen’s specifications.

The new versions comprise two MT models: the MTF flight machines, where items are loaded directly onto the conveyor, and the MTR rack machines, which use racks to carry the ware. The MTF can handle up to 8,000 plates per hour, while the MTR has the capacity to process 355 racks per hour.

The machines consist of the pre-wash, main wash, and rinse zones, plus an inlet zone, and loading and unloading zones.

Additional zones, such as extra wash zones and additional drying units, can be retrofitted to increase capacity.

In addition, Winterhalter offers neutral zones that allows the MT to accept extra-large wash items, such as crates or containers.

Heat pumps and exchangers aim to recycle the energy from waste water and water vapour, and minimise the heat and steam emitted by the machine.

Stephen Kinkead, managing director of Winterhalter UK, said he hopes the MT will help designers and operators meet the demands placed on commercial kitchens today, adding: “Functional and energy efficient technology, clever spatial planning, economical operating processes, ease of use and maximum hygiene safety – the MTs deliver in all these key areas.”