Robust warewashers to increase efficiency in the kitchen

An efficient warewasher with simple controls any member of your team can use will give you sparkling results

Warewashers are the workhorses of the kitchen, so it’s essential they withstand the rigours of operation and are easy to use – especially when back of house staff frequently change.

Nothing can stop or delay a hospitality service quite like a fault with warewashing equipment and in many cases this can be caused by user error. It’s therefore vital that the appliances are designed for simple operation and that all personnel are appropriately trained.

So how is the supply chain pulling together to help in this regard? For the Classeq brand, part of the Winterhalter group, this is reflected in the relaunch of its undercounter warewasher range. It has reduced its model variety from 16 down to four in two sizes: C400 and C500, available with or without an integral water softener. Each machine can be set or easily switched between glasswashing and dishwashing functions, and Classeq has prioritised ease of use and reliability in its product development, using feedback from trials at hospitality venues across the country.

One of these trials took place in Norden near Rochdale. The Hop and Vine, a small tapas restaurant and bar, and the Cap and Whippet, a traditional micro pub, are next-door to each other and share a washing-up area. The Classeq glasswasher was installed six months ago at the sites, which are both owned by Michael Howarth. He says: “Our glasswasher has been providing both our venues with consistently clean and sparkling glasses, using only the super-quick two-minute wash cycle. Not only have our team commented on how easy the glasswasher is to use with its two simple controls buttons, but they also said the ease with which they can clean down the machine at the end of a busy shift is excellent.

“Over the festive period, when we were even busier, the glasswasher performed brilliantly, continually washing our glasses hour after hour. We couldn’t be more pleased with its performance and ease of use.”

Total training

The right training is key to limiting user errors and manufacturer Meiko offers to assess how much training staff will need during the specification process. The firm’s UK managing director, Paul Anderson, says: “Some sites might run several shifts, so training may have to be provided continuously depending on the site’s requirements. Each package is tailored to customers’ needs over the lifetime of their Meiko equipment.”

Meiko machines are also designed to prevent misuse, with the majority featuring blue colour coding on parts that must be regularly cleaned, such as filters and wash arms. An automatic hood and rack detection system are available on the M-iClean H and HXL single and double basket dishwashers, popular with small to medium-sized restaurant kitchens, and their touchscreen panels can be moved to the operator’s eye level.

Continual staff education is a mission for Swedish brand Nordisk Clean Solutions, too (known as Granuldisk until last year). It has implemented SIMpel, consisting of a QR code sticker which acts as a gateway to a unit’s personalised online portal. The portal enables instant access to online resources, such as manuals, how-to videos and video troubleshooting guides. This means staff can easily be educated on optimal operation of Nordisk’s latest generation X2 Master hood-type universal washer, which can clean regular loads as well as pots, pans, gastronorm containers and other cookware with minimal pre-washing. Nordisk is also experienced in engaging with end users over live video to train both individual operators as well as whole teams.

Maidaid believes that purchasing a dishwasher is more than just buying a stainless steel box. It feels that its crucial difference is working hand-in-hand with its sister company, Crystaltech, dedicated to appliance commissioning and servicing.

Maidaid’s public sector manager Simon Parry notes that installation is vital for the smooth overall running of an operation: “It’s the simple things, such as the correct levelling of the dishwasher, ensuring tabling works and that baskets slide freely. That’s before we even get to checking detergent, rinse aid, dosing levels and water softener settings.”

The sister companies collaborate to offer training on not just machine operation, but also all the extra hints and tips for maintenance and everyday use, such as types of chemicals, how to rack correctly, (smallest wares at the front, larger at the back), shutdown and cleaning.

Proven robustness

Operators are always looking for proven technology to ensure uninterrupted running, and this is especially important for warewashing. At the Best Western Mount Pleasant hotel in Doncaster, director Richard McIlroy received such reassurance from utensil washer manufacturer Jeros.

He says: “The Jeros utensil washer is a key component of this busy, seven-day-a-week, 24-hour-a-day operation. The washer provides consistent and excellent results for our kitchen and, combined with ease of operation for our staff, it is the perfect solution for us.”

The firm’s range is purposefully kept simple, with minimal buttons, and is designed to be used by a variety of skill-sets in different settings. Operation is carried out by a push of a single button and a drain pump is included as standard.

Another option is Electrolux Professional’s green&clean series, available in undercounter models for front of house, alongside hood type, dual-rinse rack and multi-rinse rack formats for back of house. To help keep the appliance up and running, the range is equipped with the automatic ZeroLime descaling device, meaning heating elements can continue operating efficiently. The ClearBlue filtering system helps to keep water clean, reducing up to 95% of food residue, which helps minimise downtime.

UK and Ireland foodservice partner sales manager Alex Reed says: “All our dishwashers are ergonomically designed to keep strain on staff to a minimum.” The washers include features such as a counterbalanced door equipped with springs for soft opening and closing, and a user-friendly control panel with clear icons.

Whatever the venue, it is clear that carrying out a little homework before a warewasher purchase, ensuring the unit is robustly and ergonomically designed, and that the brand can help to support sites with training throughout a machine’s life, will pay dividends down the line.

The six soaking sins and their solutions

Warewasher connectivity can play a key role with staff training as it allows venues to monitor appliances and ways to improve operation. For example, Winterhalter’s Connected Wash system will let sites knowif the machine is not being shut down correctly at the end of service.

The manufacturer has pooled its data to find the most common mistakes that kitchen staff make when operating dishwashers and glasswashers, with the top six ‘sins’ and their solutions.

Not pre-rinsing

As well as potentially damaging the machine, this could slow down operation.

Solution: Pre-rinse dirty dishes and check and clean filters regularly.

The filter cylinder is missing

Operating the machine without this filter can lead to serious damage to the wash pump.

Solution: Always replace filters after cleaning and regularly check that they are in position.

Opening the door too early

If the rinse cycle hasn’t finished, then the wash items may still have detergent on them, resulting in an unhygienic wash.

Solution: Wait till the machine has finished the wash cycle completely before opening it.

A badly loaded rack

If there are any blockages, the wash arm will be blocked and won’t rotate properly, giving poor results.

Solution: Staff need to check the racks are properly loaded, especially with large or unusually-shaped dirties.

Running out of salt

Not only will results be poor but also scale will build up and damage the machine.

Solution: Top up the salt regularly.

Running out of detergent

A basic error, but it results in items not being washed properly or hygienically.

Solution: Check and fill detergent as required.

Clean bill of health

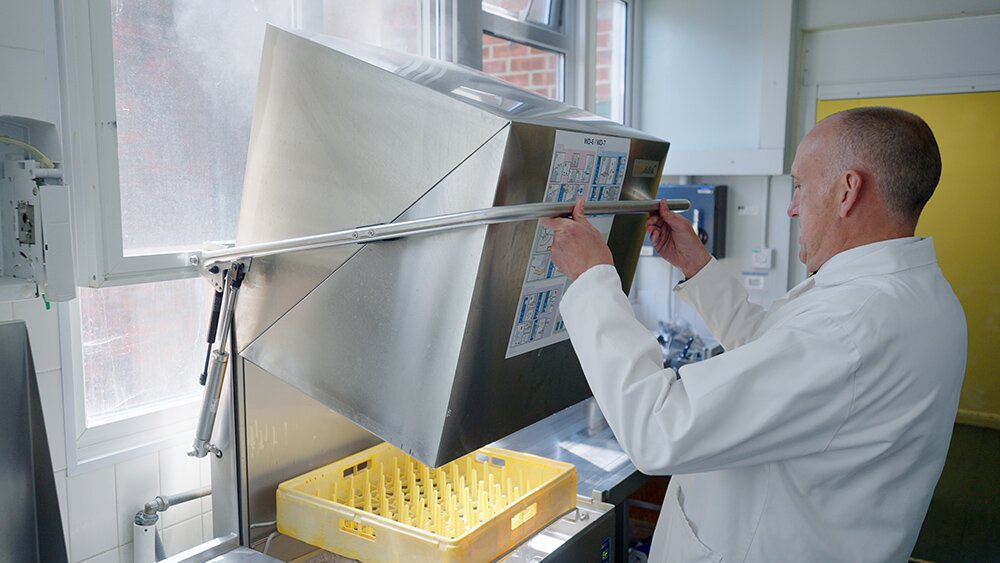

For Paul Straughair, catering manager at Salisbury NHS Foundation Trust, the preparation of around 2,000 meals per day for patients, staff and visitors in Salisbury District Hospital means the kitchens need to run like clockwork.

“We are a 480-bed hospital with two busy restaurants,” he explains. “The equipment we use in our kitchens has to cope with this level of demand and has to tick a lot of boxes for us internally. Carbon footprint is a key consideration for the trust and our equipment has to be efficient and robust so it will last.”

The site has two Wexiödisk WD-BS flight-type machines, a WD-7 dishwasher in its Hedgerows Café and a WD-100 GR, a potwash machine. The second flight machine is a recent addition to keep up with high demand, after Straughair was impressed by seven years of reliable operation from the first.

“Our first flight type hasn’t required any significant maintenance in seven years and that’s just unheard of,” he says.

One of the key features that appealed to the hospital is the appliance’s stainless steel elements: “Inside the machine, the spray arms are stainless steel, whereas other dishwashers we’ve had, they are plastic, and then the caps blow off and disappear and you’re stuck, you’ve lost pressure from the machine,” says Straughair. “Our new flight type also has a great touchscreen control panel so it’s easy to change speed and temperature and it monitors all our hazard analysis and critical control points requirements too.”

Suppliers

Classeq www.classeq.co.uk

Electrolux Professional www.electroluxprofessional.com

Jeros jeros.uk.com

Maidaid www.maidaid.co.uk

Meiko www.meiko-uk.co.uk

Nordisk www.nordiskclean.com

Wexiödisk www.wexiodisk.com/en

Winterhalter www.winterhalter.com/uk-en