The upside of downtime: How to put your kitchen equipment in hibernation for lockdown

Kitchens across the land may be sleeping, but now is the best time to ensure all your kit is closed down properly and that it’s maintained and ready to be started up again for the grand reopening. Lisa Jenkins reports

As we approach the end of the seventh week of lockdown, kitchens in restaurants, pubs, bars, contract catering sites and hotels across the UK remain closed. But closing a kitchen isn’t a simple case of turning equipment off and locking the doors.

Tim Bender, sales director for Hobart UK Equipment Division, says: “It goes without saying that prime cooking equipment is some of the most valuable real estate in a dining establishment.

“Ordinarily, the day-to-day upkeep is crucial to a kitchen’s smooth operation, but now more than ever, faced with an indefinite hiatus in usage, it’s incredibly important to know how to ‘mothball’ effectively, safeguarding an incident-free return to full capacity when the industry finally gets back to business.

“When the call comes down the line to reopen, operators shouldn’t let poorly maintained equipment be a barrier to recovery.”

When the call comes down the line to reopen, operators shouldn’t let poorly maintained equipment be a barrier to recovery

Bender suggests that essential tasks include removing and cleaning all pans and grids from equipment and, for kit with built-in wash systems, ensuring a cleaning cycle is run on a regular basis. Machines with built-in backup batteries, will need running for approximately 30 minutes a week to ensure the battery remains charged, and griddles and solid tops will need to be kept clean, dry and lightly oiled.

Steve Hemsil, sales director for UK and Ireland at Welbilt, adds: “Our Convotherm combi ovens should be shut down by first completing a deep-clean cycle, then switching off the unit and cleaning the air baffles, suction panel, door gasket and glass door by hand. The door of the unit should be left open to allow the cooking chamber to dry. After this, all supply lines to the oven can be disconnected.

“The restart procedure involves flushing water supply lines before connecting to the oven, checking the cleaning rotor, switching the unit on and completing a final deep-clean cycle.”

Hemsil also urges operators to use whatever shutdown time remains to explore the full capability of their equipment. Many ovens such as the Convotherm have far greater functionality than is used, and many of these, such as the ecoCooking mode, can save businesses money and resources when returning to full operation.

Steve Hobbs, director of Grande Cuisine UK, supplier of professional cooking appliances such as Adventys, Athanor cooking suites and modular Mareno ranges, is looking forward to getting his customers back up and running again.

“In the short term, if you can access your premises in line with government guidelines, we recommend you ‘fire up’ any pieces of equipment that have been standing idle and run them for at least 30 minutes, This includes ventilation and extract systems.

“By keeping items operating, if only on a weekly basis, you will reduce the risk of equipment seizing up through a prolonged period of inactivity. The last thing any business will want once this situation is over and they are able to operate again is an expensive repair bill.”

Simon Lohse, managing director of Rational UK, says it couldn’t be easier to protect and mothball Rational equipment for periods of inactivity.

“With the VarioCookingCenter, it’s simply a matter of giving it a good clean and disconnecting it from the water and power supplies. For combi-steamers, it involves disconnecting the water, power and gas supplies to the unit. Operators should also ensure there is no water remaining in the system that could stagnate in the pipes, allowing germs to form. This should be done by flushing about 10 litres of water through the system before shutting it down. The process will vary slightly, depending on the combi steamer model.

“To restart the combi steamer, first restore power and water supplies, and use the hand shower to rinse the wash feed system clean. Then run the unit in steam mode for 30 minutes, before finally running a short cleaning cycle. This will ensure that your equipment is fully clean and ready to go.”

Rational has a series of online training videos available and its app includes videos and tutorials on every aspect of programming, adjusting and cleaning the units.

Steve Elliott, sales director, Valentine Equipment and CuisinEquip, says the company is offering up a selection of training presentations on its equipment. “We have been sending these out to our customers every week or two. Some of the dealers have told us that they are using this period of relative inactivity to make sure that they have all the latest information on the ranges.”

Stuart Flint, training and demonstration manager at Electrolux Professional, says ongoing training is vital. “The current situation prohibits face-to-face training, but there are still ways that caterers can engage in learning and training to prepare them for when operations start up again. We have sessions covering the full range of Electrolux Professional’s foodservice portfolio, and partners are free to attend training remotely via video conferencing software.”

Help from Lincat comes in the form of the Lincat Chef-line, a support line to support businesses with questions on menu development, best practice or online training on products.

##Keep it clean

Once businesses start to come back online, hygiene is going to be a priority. Kitchen porters and the best warewashing equipment will be crucial.

Basix hand wash stations (pictured) from Mechline Developments feature a knee-activated button to dispense water, ensuring contactless control.

Wexiödisk offers a high-end, hygiene-led cutlery sorting solution, the ACS-800, which minimises the need for kitchen porters to touch cutlery after being washed. An inbuilt logistics system with a buffer band and sorter automatically transports and sorts cutlery and can be pre-programmed to separate up to 3,600 pieces of mixed cutlery per hour.

David Glover, UK and Ireland country manager at Wexiödisk UK, explains: “Many public sector and B&I venues operate a part self-serve/canteen-style catering regime that involves the customer picking up their own cutlery. This machine allows operators to remove all points of human contact with the cutlery before it is picked by the customer.”

Paul Anderson, managing director at Meiko UK, says: “Like many manufacturers and suppliers during the Covid-19 crisis, Meiko has benefited from building a stockpile of spare parts to cope with Brexit issues. The factory in Germany continues to function and we continue to receive deliveries of parts and machines as usual.

“The future will look different and, as we will inevitably recover to experience an alternative normality – from a dishwashing perspective – I expect to see a considerable increase in equipment maintenance, servicing, repair and refurbishment, as those that have suffered financially aim to extend the working life of their equipment, rather than buy new.”

##The FEA Equipment and Systems Preservation guide reopening advice

The Foodservice Equipment Association (FEA) and its members have pooled their expertise to put together a guide for any foodservice operator looking for information on how to restart equipment for re-opening.

- Clean everything thoroughly before you start.

- If you’re unsure about any appliance’s operational status, get it serviced. Similarly, if anything doesn’t feel right – for example, a button that won’t push – then don’t force it. Call an engineer.

- As much as possible, check everything is in good order (for example, do a thorough visual check) before switching on.

- Treat equipment as if it is new – follow the user manual, run through the start-up procedure, do a dry run, then start it up and run the machine.

- Note that many manufacturers will have instructions and advice online – if the answer isn’t there, give them a call.

- For gas equipment: check the appliance as well as the ventilation and interlock systems. If in any doubt at all, call in an engineer.

- For electric appliances: again, if it’s not working, and you’ve checked the supply is switched on, then call an engineer.

- For any appliance using water (beverage systems, etc), run water through the system to flush out any standing water that might have been left in. Thoroughly clean the system.

- For refrigeration: after cleaning, turn on and check that it reaches the correct temperature before loading.

- Give warewashers a run through on empty.

- Light equipment: where possible and safe to do so, dismantle and give the appliances a thorough cleaning.

- Grease management systems: recommission according to the manufacturer’s instructions. If external grease traps were not emptied at lockdown, get a contractor to empty them. Fill bio-dosing systems.

- Waste management systems such as FWDs: recommission according to manufacturer’s instructions.

##In the cooler

Refrigeration manufacturer Williams has several guides to decommissioning cold-rooms and refrigeration during shutdown.

Malcolm Harling, sales and marketing director, explains: “As with the other guides, the cold-room advice can be applied to most refrigeration brands. The key is to do it right so that the equipment is protected during the lockdown and, when turned back on, it’s safe and working effectively.”

Alongside the key points, the cold-room guides include supplementary cautions and pieces of important information. For example, some cold-rooms have a power failure alarm, which normally runs from a 9V battery. Williams advises that the control panel should not be opened in order to disconnect the battery when shutting the cold-room down, rather, the battery should be replaced by an engineer when the unit is recommissioned.

Simon Frost, director UK and Ireland, Hoshizaki, adds: “A commercial refrigerator is one of the most important pieces of equipment in the kitchen for keeping both raw and cooked foods safe and slowing the growth of bacteria.

“We urge caterers to regularly disinfect the surfaces, shelves and handles of their refrigerators in addition to regularly cleaning filters, so that safe temperatures can be maintained.”

##Adapting to demand

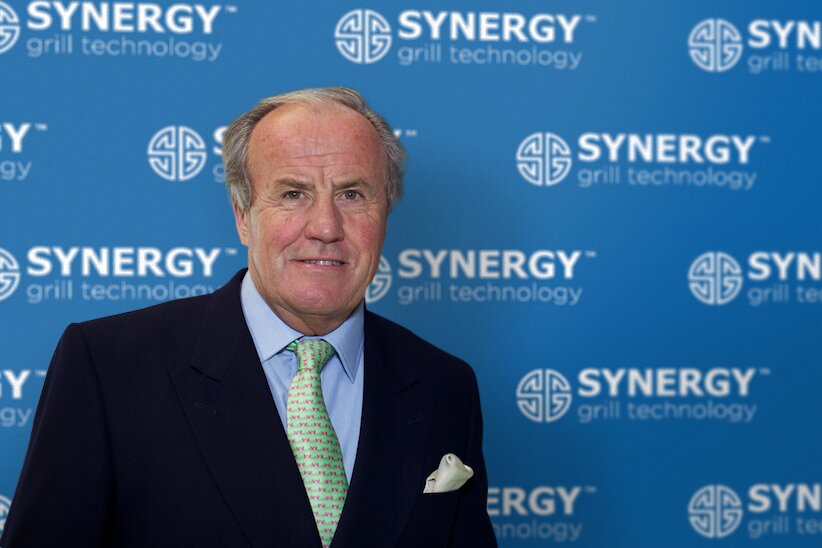

British Grill manufacturer Synergy Grill Technology has introduced new leasing schemes for operators offering a delivery and takeaway service during lockdown.

Justin Cadbury, chief executive and chairman (pictured), said: “Our partnerships with a number of British leasing companies will allow food outlets to lease a brand-new Synergy Grill from just £35 per week, rather than having to pay for one outright, and cut overheads straight away.”

Target Catering Equipment has stepped up its support during the crisis with the manufacture of medical-grade, stainless steel kit, such as wash stations, dishwashers, and system to wash mattresses and bed pans, all able to disinfect and remove pathogens, including coronavirus.

Managing director David Pedrette says: “We prioritised all orders from the NHS, healthcare, care and public sectors, and military, who are all working so hard and doing such a great job.”