Guard against downtime with maintenance plans and leasing contracts

As coronavirus has proven, anything can happen, so operators would be wise to future-proof their businesses by servicing and maintaining equipment

A lthough pandemic restrictions have eased, the repercussions of the extreme downtime and big losses that have hammered hospitality for the past two years have left their mark. Operators have found that flexible finance and kit maintenance are now key tools in the sector’s post-lockdown recovery.

Many operators who needed new equipment for reopening and could not afford to pay for it outright have found it hard to secure credit from traditional banks, reports eCatering owner Duncan Evershed.

Fortunately, many suppliers have stepped up to the plate with alternative payment solutions to plug this gap in customer cash flow and cushion the cost of investing in their future with the most up-to-date models.

eCatering, which supplies a range of professional catering equipment from food prep and cooking appliances to refrigeration and stainless-steel kitchen furniture, turned to the innovative IwocaPay solution launched by Iwoca last year as an alternative to finance at the point of invoice.

IwocaPay offers customers instant credit (in the form of extended payment terms via a PayLink embedded into emails or invoices) and protects the sellers by paying them upfront as soon as the buyer accepts the offer.

“It meant we were able to start offering foodservice operators a ‘buy now pay later’ service. Operators were able to get the equipment they needed straight away, but were able to spread the cost of it over 90 days, with the first 30 days free,” explains Evershed. “It has become a very popular option for our customers, and helps both us and them with cash flow as the industry recovers from the pandemic.”

It will remain an important resource as the resurgence in self-isolating diners hits restaurants with heavy cancellations and reduced covers, predicts Evershed: “Being able to utilise a stable ‘pay later’ method for both us as a supplier and our customers is therefore key, and we look forward to also using it beyond the pandemic.”

One step ahead

Leasing has proved to be a popular alternative finance option during uncertain times and is a solution that Intelligent Appliances, a new company designed to offer problem-solving and sustainable equipment, has used since its mid-pandemic launch in 2021.

Intelligent Appliances is the exclusive UK distributor of the Urban Culitavator, an automated indoor kitchen garden for caterers to grow their own herbs and microgreens while reducing air miles and supply chain issues. The group teamed up with Tower Leasing to offer personalised terms and costs to lease the build-in and freestanding cultivators (priced from £4,950 to £18,235) for between two to five years.

“This allows caterers to manage cash flow while still investing in the latest assets and technology to allow them to remain competitive. Equipment upgrades can be added in at any stage throughout the agreement, as well as restructuring the payment schedule,” says founder Gary Baker. “The tax benefits of leasing are a big benefit. Caterers get 19% tax relief against corporation tax and can offset 100% of the lease investment against their tax liability.”

No fool fuel

Synergy Grill Technology’s Synergy Contract gives caterers easy access to its high-heat, low-energy and fat-carbonising grill technology as they work to rebuild their income in the face of budget cuts, failed technology and recent gas price hikes, says chairman and chief executive Justin Cadbury.

The deal means no large upfront deposits and fees, plus the promise of immediate payback in terms of energy savings, which Cadbury estimates at 59% and 25% on gas and electric grills respectively. Operators who switch from an existing chargrill or charcoal oven can, he adds, make “hundreds of pounds” in savings from day one.

The two monthly fixed-amount lease contracts (based on the customers’ trading status above or below three years) includes the costs of installation, removal of the old grill and hire of the new equipment. Cadbury adds: “In both cases, the fuel savings are better than the cost of the monthly contract itself, ultimately saving operators money from day one of their contract”.

“When thinking about professional catering equipment, ongoing servicing and maintenance is as important as initially making the right purchase,” observes Gary Thacker, director of national accounts at Fri-Jado UK. Its sister company, Tec Line, offers nationwide pre- and post-sales support – including in and out of warranty service and preventative maintenance contracts – for Fri-Jado’s range of food prep and display equipment and rotisseries, achieving an impressive first-time fix rate of 95%.

“Though not ideal, the various periods of downtime that venues have faced due to national restrictions equally provided many operators with a unique chance to carry out thorough maintenance checks on their equipment,” notes Neill Pearson, service director at Jestic Foodservice Solutions.

He warns that the relaxation of lockdown rules should not signal any de-prioritisation of gold-standard planned preventative maintenance measures: “This is because preventative maintenance is designed to get ahead of a potential issue by checking for wear or faults, therefore significantly reducing downtime caused by breakdowns in a busy catering environment.”

Giving up downtime

Research last year by water filtration specialist Brita Professional found that 17% of professional kitchens had reduced their equipment services and maintenance budgets – but the costs of failing to pre-empt potential problems can be considerable.

According to Keith Mackie, managing director at Hobart Service, planned preventative maintenance can reduce kitchen downtime by up to 20%, while Karl Cundill, partner at catering and facilities management consultancy Litmus Partnership, estimates that the time and cost of repairing failed equipment on the hoof can be three to five times more expensive than planned corrective repair.

Because many modern appliances are made from complex and intricate parts that require expert knowledge, Pearson at Jestic believes: “The most important factors when it comes to selecting a planned preventative maintenance contract is the level of experience of the provider and the extent to which the service covers the area in which you are located.”

The 50 engineers at its nationwide service and repair division, Jestic Technical Services, combine 40 years of experience. The company has invested in expanding its service team and increasing its stock to achieve a response rate in excess of 90%.

It offers different levels of cover to suit individual site needs, such as priority response times and planned and scheduled visits through bespoke contracts. Meanwhile, Jestic’s new Qlik software allows operators to determine if their equipment is costing too much to maintain by analysing the whole-life cost of appliances and highlighting those with high levels of issues that may be worth replacing.

Intelligent Appliances offers an eco-friendly end-to-end service on its Urban Cultivator, which Baker describes as a “zero-mile diet on a plate”. After-sales care includes a five-year warranty, free starter kit, delivery, set-up, in-person training for the catering team and on-going support to help maintain the lifespan of the product. When its commercial retirement day arrives, the cultivator is repurposed and rehomed where possible by national charity Emmaus UK.

“Around 150,000 tonnes of large appliances are disposed of each year, with only 35% being reused or refurbished,” explains Baker. “Commercial catering equipment – especially that which is poorly maintained – is a major contributor to carbon emissions too.”

Valentine and Cuisinequip offer a comprehensive three-year parts and labour warranty on its stainless steel fryers (plus 20 years on the pan itself), but sales director Steve Elliott believes customers should also take out an adequate preventative maintenance plan with a certified service provider.

“We recommend that when it comes to premium service and preventative maintenance, operators service their fryers like they would their car as ultimately, prevention is often better than a cure,” explains Elliott. “When it comes to achieving a safe, compliant and long-lasting lifespan of your catering equipment, operators should combine quality equipment from leading manufacturers, with a regular, comprehensive service and planned preventative maintenance schedule.”

See problems before they happen

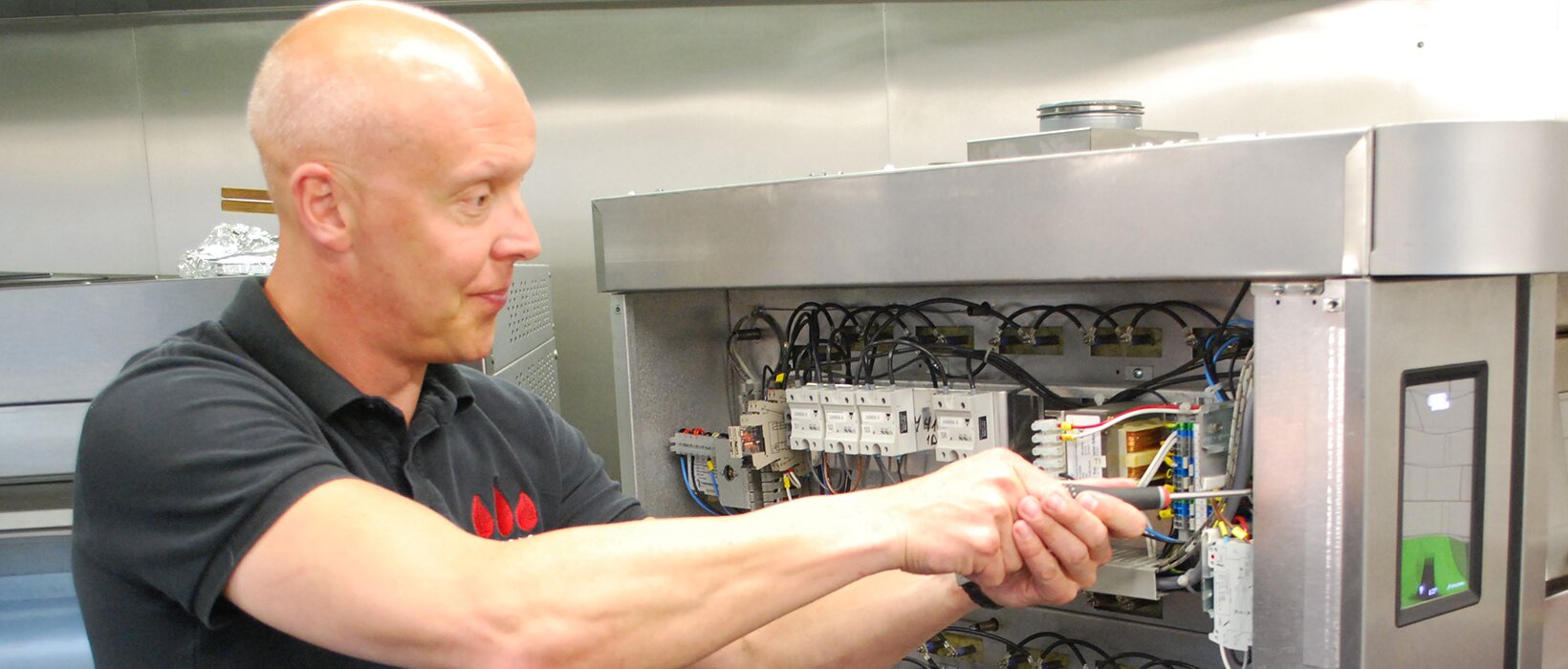

Oven supplier Unox UK is harnessing smart technology to help hospitality and foodservice operators make the most of their kit and keep it running in tip-top condition.

“At Unox, we believe that it is important to not just manufacture and sell market leading catering equipment, but also back it up with award-winning after-sales service and support,” explains managing director Scott Duncan.

The basic Unox package includes a standard two-year parts and labour warranty and tailored planned preventative maintenance contracts backed by a nationwide network of factory-trained engineers. It also empowers customers to remotely monitor the performance of their oven via an account on a dedicated website using its free downloadable Top.Training app. This links to connected technology built into the ovens that enables Unox’s innovative Data Driven Cooking (DDC) platform.

“View consumption and usage reports, check an ovens’ wash cycle status and most crucially, remotely diagnose faults and issues before they escalate,” says Duncan.

“Working with our UK-based support team, fault-diagnoses identifies a potential problem and allows it to be fixed, often before it worsens – ultimately reducing costly downtime.”

The DDC platform also offers customers a complimentary LONG.Life4 extended warranty package that stretches the parts warranty to four years if the ovens were installed and commissioned by an approved partner.

Unox care support goes beyond service to span bespoke culinary training and menu development including an on-site session with a regional active marketing chef that is tailored to the site and step-by-step guides on everything from oven basics to the most advanced cooking technologies via the Top.Training app.

Suppliers

Brita Professional www.brita.co.uk/news-stories/professional/managed-services

eCatering www.ecatering.co.uk

iwocaPay www.iwoca.co.uk/news/introducing-iwocapay

Fri-jado www.frijado.com

Hobart www.hobartuk.com

Intelligent Appliances www.intelligentappliances.co.uk

Jestic Foodservice Solutions www.jestic.co.uk

Litmus litmuspartnership.co.uk/services/facilities-management

Synergy Grill Technology synergygrill.com

Unox www.unox.com/en_gb

Valentine and Cuisinequip www.valentinefryers.com