Spotlight on: Robots

Automation can rescue hospitality from daily drudgery and operational headaches, saving time, paperwork, and giving staff valuable time with the customer

Hospitality businesses face pressure from all directions, fuelling the need for them to seek out more efficient ways to operate, with one over-arching solution involving the rapidly developing field of robotics and automation.

For years robots have been perceived as purely a gimmick when deployed front of house, but serious staff shortages have led to a reappraisal and they are now being deployed in meaningful ways at restaurants such as Bella Italia, where units are delivering food and clearing plates.

But where robots and automation are really beginning to have a revolutionary impact is within the back of house operations. We are undoubtedly on the cusp of the adoption at scale of robots to replace some of the repetitive human tasks within kitchens. The fast-food brands will be the first adopters, but the widespread use of such technology in varying capacities across the entire food and beverage industry looks inevitable.

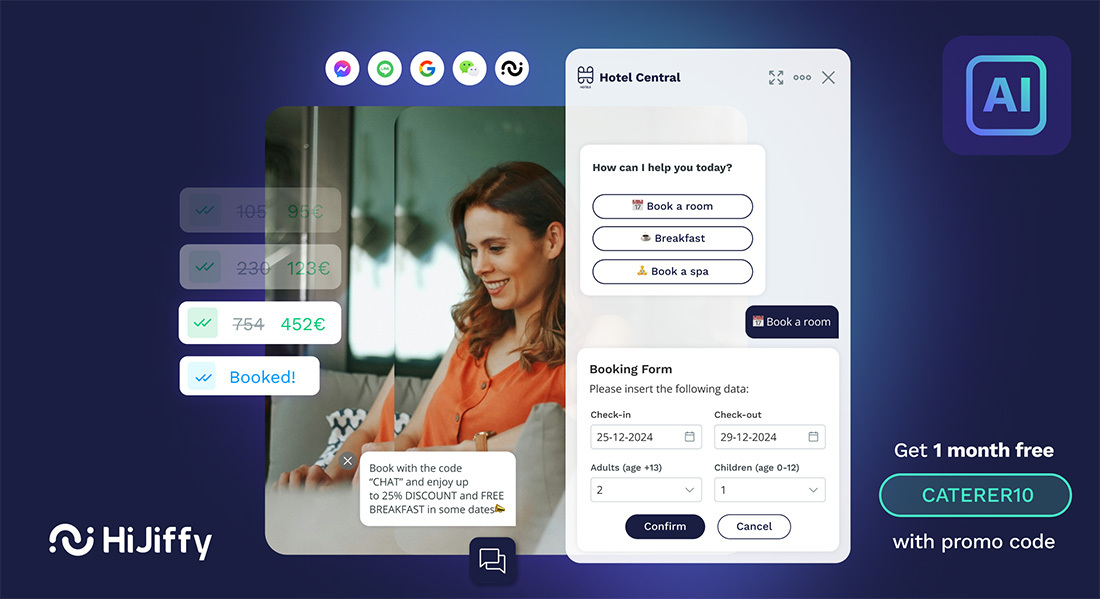

While robots are in the early stages of their advance the use of automation is already widespread and will continue to drive massive efficiency gains and cost savings across all types of businesses. The rapid advances in artificial intelligence (AI), and the ramping up of competition between technology providers is driving down the prices of automation solutions and encouraging adoption across all parts of the hospitality industry.

Tech update: Automating the fry lines in the quick-service industry

Within the quick service restaurant (QSR) industry the fry lines are at the heart of most operations, but overseeing them is the least appealing role. As such, it is proving increasingly difficult to recruit people for these jobs.

Recruitment issues are the primary reason why a leading QSR brand is currently trialing the new automated fry line, FRYR, from Karakuri that complements its existing food portioning/assembling robot SEMBLR.

Barney Wragg, chief executive at Karakuri, says: “People have been trying to automate the fry line for 10 to 15 years. The technology is very complex and needs to be reliable and available at the right price point. Our robots are like large Internet of Things devices with phenomenal power that feed data into the cloud where we monitor, optimise and update the device’s capabilities.”

The complex issues the FRYR robot is addressing are the precise timings and tasks each restaurant stipulates in its standard operating procedures. It is tough for a person to handle as there will typically be between four and 16 fry baskets to juggle at busy times. Research from one fried chicken chain has shown 45% of fries are sold either undercooked or going cold. “They will all be running them in parallel and each with timers. It’s complicated to decide the quantities to fry and the cooking times required for these amounts and also managing the oil temperatures,” says Wragg.

FRYR uses AI to optimise the amounts of food required to fry, based on the time of day and previous activity. This capability not only helps restaurants overcome the recruitment issue but also improves the quality of the end product.

Case study: Orbisk at Accor

Food waste is not only an increasingly sensitive subject but economically catastrophic for margins, which is leading businesses such as Accor to implement technology and automated solutions to help it reduce wastage levels.

Richard Beks, co-founder of Orbisk, says Accor Hotels in the Netherlands along with Novotel, Sofitel, Compass and Center Parcs have adopted the Orbisk technology in their kitchens. When food is thrown in the bin a photograph is taken of the items and a scale below the bin weighs the waste.

The AI software in the Orbisk solution recognises the items and, during the on-boarding period (the first 100 days) of operation, it can build up a detailed picture of what is wasted and determine patterns and issues that can be addressed. It can recognise if the items are leftovers from customers’ plates, from the buffet, or from chefs’ chopping boards.

Along with identifying waste issues that are specific to an outlet there are also generic waste problems, such as reducing salad choices on a Friday because people tend to choose less healthy items on this day of the week. There are also the universally high levels of waste generated by buffets, with Beks revealing that 20%-50% of buffet foods are binned. At Accor it was possible to hire a chef to cook ordered items for guests as the removal of these products from the buffet saved sufficient money to pay for this additional employee.

These insights are fed back to the organisation through the Orbisk dashboard. This has helped the Accor sites to roughly halve its level of waste, which might be cut further when it is able to use predictive capabilities. According to Beks, the company is close to releasing this version to its clients: “This could tell the chef to bake fewer croissants tomorrow and also automate the grocery ordering to ensure menu optimisation. We’re currently testing this with some caterers in The Netherlands.”

Case study: DocMX at Voco St David’s Cardiff

Hospitality companies suffer from the way information is processed, stored and shared across all aspects of their operations. The manual processing of information from many disconnected systems and mediums is incredibly slow, costly and laborious, and damaging to the environment. Data security is also a huge and growing concern among hotels.

Voco St David’s Cardiff has automated the handling of this information with the adoption of DocMX. Neil Parry, hotel manager at Voco St David’s Cardiff, says the solution has created a single portal that as a hotel manager allows him to painlessly review all financial reports.

“There is no need to review reams of paper or spreadsheets and I have the ability to send questions directly from the portal to departments or users if I have any questions or queries. I am able to review these documents from my iPad off-site at my leisure without the need to print, sign and scan. All data is automated and easily read and understood,” he explains.

The solution has brought many benefits, according to Parry, who adds: “From a time perspective it has increased my productivity immensely and I am able to review and authorise remotely and effectively. It has brought our compliance scores up, as well as made the reporting and end-of-day process easier for our front of house and back of house teams. I have seen a positive shift in the team’s approach to financial reporting with them having better oversight of the data and results.”

Case Study: Pudu Robotics in Bella Italia

Bella Italia has been using robots in its restaurants to improve operational efficiency, reduce labour costs and provide a unique guest experience.

The robots are used to perform repetitive tasks, such as delivering food to tables and clearing plates. By taking over these tasks, the robots allow the waiting staff to focus on more valuable activities, such as communicating with guests, solving problems and ensuring a positive dining experience. This division of labour not only benefits the restaurant but also leads to an improvement in tips for waiting staff.

Greg Gibbons, operational support director at the Big Table Group, which operates the Bella Italia chain, says: “One of the significant advantages of using robots is their consistency and reliability. Robots don’t get tired or need breaks, so they can work continuously without any reduction in productivity. The robots at Bella Italia provide a seamless and efficient service, delivering food and clearing tables promptly, improving the speed of service and reducing wait times for guests.”

This has resulted in significant improvements in sales per labour hour, spend per head and guest metrics. These benefits are especially pronounced during busy periods when the robots can support the waiting staff, reducing the time and distance spent carrying plates, which allows the team to focus more on their guests. Additionally, the robots offer a unique and interactive experience for guests, enhancing their overall dining experience.

“The robots’ impact on the guests has been overwhelming and positive, as evidenced by the massive social media coverage they have received. Guests are intrigued and fascinated by the robots and often take photos and videos with them, posting them on social media platforms, which leads to increased brand visibility and, ultimately, increased sales,” says Gibbons.

The use of robots in hospitality is not only beneficial to Bella Italia but also to the industry as a whole, according to Gibbons, who says it allows one to look at efficiencies in everything they do while maintaining guest service.

Case study: Choco at Smith & Brock

Lost orders, incorrectly communicated orders and unco-ordinated invoices and statements are a major issue for restaurants. This problem is being addressed by a growing number of restaurants that are digitising and automating the fresh produce ordering process.

Among this group are Red Chutney, Le Gavroche, Olive & Squash and Zafferano, which are using a solution from Choco to place orders with the likes of high-end food supplier Smith & Brock. They are enjoying the benefits of a smoother ordering process, according to Nick Fowler, co-founder of Smith & Brock, who says his restaurant clients typically use the phone and Whatsapp for placing orders but this is difficult to manage across many accounts. Choco is an app-based solution that has Whatsapp-like functionality.

“We wanted a halfway house between a bells and whistles procurement system [used by our contract caterer clients] and Whatsapp. With Choco we upload our catalogues, codes and prices,” he says, and the orders can then be placed directly through this portal.

By placing orders via the app there is less processing required, more accuracy and the system automatically generates invoices, thereby giving chefs visibility of their costs at any given time and avoiding the need for Smith & Brock to separately generate this paperwork. The system has also improved the ability of the company to process orders and pass them swiftly onto its pickers, who will be handling around 300 orders each day between 9:30pm and 11pm.

Although many restaurants are still using the phone and Whatsapp to place orders Fowler says there is a general move in the direction of automating processes. Only 8% of orders were undertaken electronically – contract caterer clients via EDI – but this had grown to 32% by December 2022, fuelled by the use of Choco by a growing roster of restaurateurs.